Have you ever sliced potatoes, cheese, or crisp cucumbers, only to have every slice stick to the blade? It’s common kitchen frustrations that slow you down. Or perhaps you’ve seen a large butcher’s cleaver with a big, mysterious hole near the spine.

It turns out those holes aren’t just for show.

A knife with holes in the blade is a specialized tool designed with strategic cutouts to solve specific problems. From reducing friction and food sticking to improving balance and even allowing for one-handed opening, these holes are an excellent example of form following function.

This design appeals to both home cooks looking for a smoother slicing experience and professionals who demand efficiency and performance. Let’s dive into why these holes exist, what they do, and whether a holed blade is right for you.

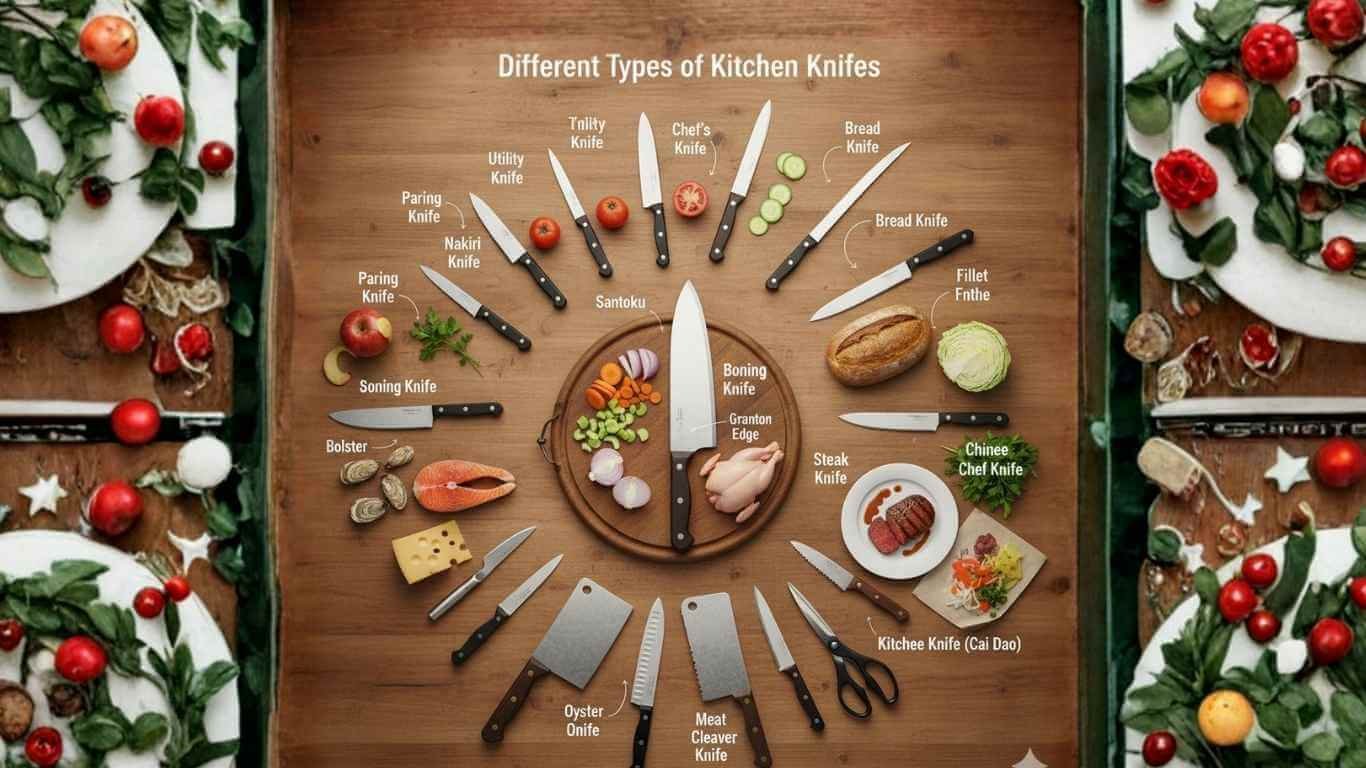

Types of Knives With Holes

You’ll find holes in a surprisingly wide variety of knives, and their position and size tell you everything about their purpose.

- Cheese Knives: This is the most common example. Knives designed for soft or semi-soft cheeses (like Brie or Gouda) often feature multiple holes. These “Swiss cheese” cutouts prevent the cheese from sticking.

- “Non-Stick” Santoku or Chef’s Knives: Some kitchen knives, like those from brands such as Seido or Victorinox, use a series of holes along the blade instead of a Granton edge (the oval dimples you often see). The goal is the same: food release.

- Cleavers and Butcher Knives: These heavy-duty tools always have one large, distinct hole near the top corner. This hole has a simpler, more traditional purpose: hanging and storage.

- Tactical and Folding Knives: On many modern pocket knives, you’ll find a single, signature hole near the handle. Spyderco famously patented their “Round Hole Opener,” a feature that allows the user to easily flick the blade open with their thumb, making it fully ambidextrous.

Main Reasons For Holes in Knife Blades

While a single knife might have holes for multiple reasons, the benefits generally fall into a few key categories.

1. Reduced Friction and Improved Food Release

This is the number one reason for holes in culinary knives. When you slice through moist or starchy foods (think potatoes, apples, wet cheese, or raw fish), a vacuum-like suction forms between the flat, wet surface of the food and the flat, wide surface of the blade.

The holes break up this surface area. As the blade passes through, air gets into the gaps, breaking the suction. This means the food falls away cleanly instead of clinging to the side of the knife. This is especially critical for soft cheeses, which can smear and tear if they stick.

2. Weight Reduction and Better Balance

On larger knives, material means weight. A big, heavy cleaver can cause fatigue during extended use. Removing material with a hole can subtly lighten the blade.

More importantly, it changes the knife’s center of gravity. Knife makers and professional chefs often talk about the “balance point” of a knife. By strategically placing a hole, a manufacturer can shift the balance, often moving it closer to the handle, which can make a large knife feel more nimble and responsive in the hand.

3. Hanging and Storage (The Cleaver’s Secret)

The most practical and historic reason for a hole is storage. A large, heavy cleaver doesn’t fit safely in a standard knife block, and tossing it in a drawer is a recipe for a dulled edge and injured fingers. The large hole allows a butcher or chef to hang the cleaver on a hook or peg board, keeping it secure, sharp, and out of the way.

4. One-Handed Deployment

For folding knives, the hole is all about accessibility. Spyderco’s innovation allows you to safely and reliably open the knife with one hand, without needing a “flipper” tab or a thumb stud that can snag on your pocket. It’s a purely functional design that has become an iconic aesthetic.

The Science and Engineering Behind Blade Holes

It’s easy to see the hole in a container and understand its purpose. But how does a small hole really stop food from sticking?

The magic is all about the surfaceabout the surface area. Food sticks because of moisture adhesion and suction. The smooth, uninterrupted surface of a standard knife blade provides a large area for this to happen.

Each hole introduces an “edge” and an “air pocket.” When the blade cuts, the food’s surface can’t create an ideal seal against the metal. Air is maintained in the cutout, effectively pushing the food off. This is the same principle behind a knife that has a Granton edge, but holes provide a more extreme version of the effect.

Engineering-wise, there’s a trade-off. Removing material technically creates structural weakness. However, for any reputable knife maker, this is calculated into the design. The blade is forged and heat-treated to ensure its integrity remains far beyond its intended use. For a kitchen knife, you will never put enough stress on it for this to be a problem.

Pros and Cons: Should You Get One?

A knife with holes in the blade can be a fantastic tool, but not without drawbacks.

Practical Advantages (Pros)

- Superior Food Release: Slicing, dicing, and minceing starchy vegetables and cheeses is significantly faster and cleaner.

- Lighter Weight: A lighter blade can reduce hand fatigue during long prep sessions.

- Easy Storage: For large cleavers, the hanging hole is a safety and convenience feature.

- Unique Handling: A shift in balance can make some knives feel more agile.

Potential downsides (Cons)

- Cleaning Challenges: This is the biggest complaint. Food particles, especially soft cheese or fibrous vegetables, can lodge inside the holes. They require extra attention to clean.

- Potential for drag (if dirty): If you don’t clean the holes properly, caked-on food particles defeat the purpose and increase friction.

- Durability (A Minor Concern): While not an issue for kitchen use, a holed blade is not the ideal design for heavy-duty survival or “batoning” (splitting wood), where a full, solid spine is needed for maximum strength.

History and evolution

The earliest and most straightforward example of a holed blade is the traditional butcher’s cleaver. This design is centuries old and was born from the simple, practical need to hang a large, dangerous tool safely in a busy butcher shop or kitchen.

The use of holes for food release is a much more modern culinary innovation, likely an evolution of the Granton edge. As material science and manufacturing processes (like laser cutting) became more precise and affordable, designers could experiment with more complex cutouts to perfect the “non-stick” effect.

In the tactical world, the single-handed opening hole was a game-changer. Sal Glesser, Spyderco’s founder, introduced it in 1981. It was so effective and original that it was granted a U.S. utility patent. It has since become the brand’s most recognizable feature, widely imitated across the industry.

Expert & Chef Insights

You don’t have to take our word for it. The consensus in the culinary and knife-enthusiastic communities is that these designs, when well-executed, work.

- On Food Release: Test kitchens like America’s Test Kitchen repeatedly testKitchen repeatedly test “non-stick” knives. They consistently found that blades with holes or deep Granton dimples perform “exceptionally well” at releasing potatoes and other starchy foods compared to standard flat-ground blades.

- On Cheese Knives: As any cheesemonger will tell you, a dedicated cheese knife is essential. For soft cheeses, they always recommend a knife with large holes. They note that it’s the only way to get a clean slice of sticky Brie without it turning to mush.

- On Tactical Knives: In forums like BladeForums, users and collectors have long praised the Spyderco Round Hole for its “flickability” and ambidextrous ease of use, considering it one of the simplest and most reliable one-handed opening systems ever made.

Expert & Chef Insights

You don’t have to take our word for it. The consensus in the culinary and knife-enthusiastic communities is that these designs, when well-executed, work.

- On Food Release: Test kitchens like America’s Test Kitchen repeatedly testKitchen repeatedly test “non-stick” knives. They consistently found that blades with holes or deep Granton dimples perform “exceptionally well” at releasing potatoes and other starchy foods compared to standard flat-ground blades.

- On Cheese Knives: As any cheese monger will tell you, a dedicated cheese knife is essential. For soft cheeses, they always recommend a knife with large holes. They note that it’s the only way to get a clean slice of sticky Brie without it turning to mush.

- On Tactical Knives: In forums like BladeForums, users and collectors have long praised the Spyderco Round Hole for its “flickability” and ambidextrous ease of use, considering it one of the simplest and most reliable one-handed opening systems ever made.

Maintenance, Cleaning, and Safety Tips

A knife with holes needs extra love to stay in top condition.

- Clean Immediately: Don’t let food dry in the holes. Rinse the knife immediately after use.

- Use a Brush: For thorough cleaning, a small bottle brush or a dedicated kitchen brush is your best friend. Use warm, soapy water and gently scrub inside the holes to dislodge any trapped particles.

- Dry thoroughly: This is critical. Water can sit inside the cutouts, leading to rust spots, especially on high-carbon steel blades. Hand-dry the knife completely, paying attention to the inside edges of the holes.

- Honing and Sharpening: The holes do not interfere with sharpening. The cutting edge is solid and can be honed and sharpened just like any other knife.

- Safety: The holes don’t make the edge sharper. Treat it with the same respect as any professional-grade cutting tool.

Frequently Asked Questions (FAQ)

Does a hole in a knife blade really prevent food sticking?

Yes. For moist, starchy, or soft foods (like cheese, potatoes, cucumbers, and apples), the holes reduce surface area and create air pockets that break suction, allowing food to fall away easily.

What is the deep hole in a cleaver for?

That hole is almost exclusively for storage. It allows the large, heavy blade to be hung securely on a peg or hook. This is safer and better for the blade than storing it in a drawer.

Are knives with blade holes weaker?

Technically, removing any material makes an object weaker, but this is an engineering problem with a viable solution. Reputable manufacturers design the knife to be strong enough for its intended task. You won’t break a holed kitchen knife during normal kitchen use.

What is the round hole in a Spyderco knife for?

It’s their trademarked “Round Hole Opener.” It provides a large, non-slip surface for your thumb to grip, allowing you to easily and quickly “flick” the blade open with one hand.

Conclusion: A Tool With a Purpose

A knife with holes in the blade is not a gimmick. It is a purpose-driven design that solves real-world problems.

Whether it’s the simple, age-old utility of hanging a heavy cleaver, the tactical genius of a one-handed opening mechanism, or the culinary convenience of a non-stick cheese knife, those holes are there for a reason.

If you find yourself constantly frustrated by food sticking to your blade, or if you’re a cheese lover looking for the right cut, exploring a knife with a holed blade is a smart move. It might just be the smallest design change that makes a big difference in your kitchen.